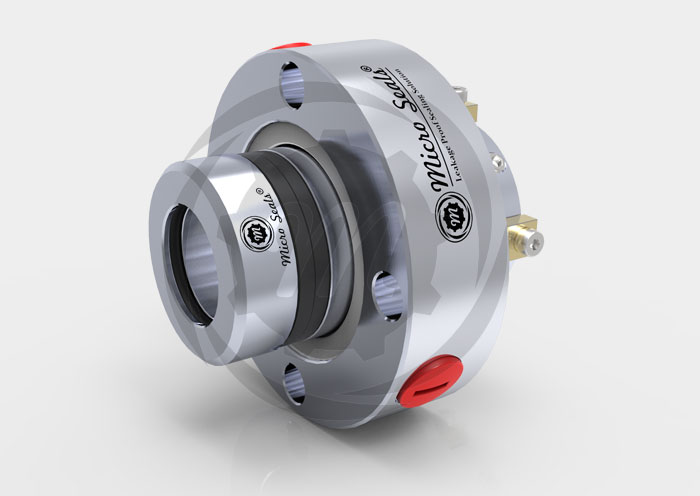

DOUBLE CARTRIDGE MECHANICAL SEALS

CD43 Cartridge Dual Mechanical Seals For Process Pumps,Slurry Pumps, Boiler Feed Pumps For Slurry and Viscous Media

Double Cartridge Seal are required for process fluids containing abrasive slurries or hazardous / toxic chemicals and require an externally supplied barrier buffer fluids to pressurize, lubricate and cool the Inboard and Outboard seal faces. This Cartridge Seal is a factory assembled double Cartridge Seal as cartridge unit specially design for slurry & viscous media. Also, this seal can be easily assembled in the equipment without need of any specific measurements. It acts as the check valve to prevent liquid under high pressure from leaking out. Owing to its rugged construction, top notch quality, and effectiveness, it is widely appreciated amongst our patrons.

Dual Cartridge Mechanical seals

Dual Cartridge Seals is a factory assembled cartridge unit specially design for slurry & viscous media.Double Cartridge Seal is a self contained unit consisting two mechanical seals in a seal chamber in any combination which can utilize a pressurized barrier fluid or a non pressurized buffer fluid.

These seal arrangements are a superior upgrade to a single cartridge Seals when it is imperative the media does not leak to atmosphere. A dual cartridge seal very often is formed with tandem configuration (face-to-back), or face-to-face configuration.

In a tandem configuration, the outer seal essentially works as backup for the primary seal.in a face-to-face arrangment,the outer seals creates a barrier. When any issue happens with the inner seal.

- Double seal

- Cartridge Unit

- Balanced Seal

- Independent of direction of rotation

- Multiple Spring arrangement

- Stationary Spring

| Seal Ring Face | : Carbon, Silicon, TC |

| Mating Ring Face | : Silicon, TC |

| Secondary Seals | : Viton / PTFE / GFT/FFKM |

| Metal Parts | : SS 3’16, 904 L. Alloy 20 |

| Pressure | : Up to 15 bars |

| Temperature | : (-)80c to (+)150c |

| Speed | : Up to 25 m/s |

| Size | : 25 mm to 150 mm |

Sludge & Syrup pump Paper Industries. Petrochemicals. Petroleum Refinery.

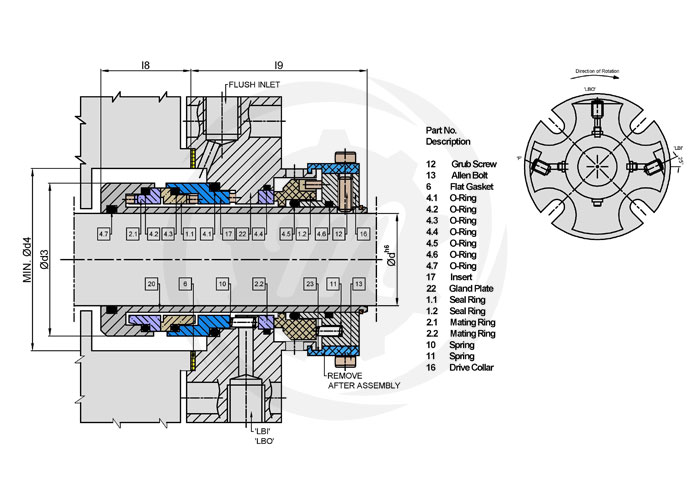

| Item No | Description |

|---|---|

| 12 | Grub Screw |

| 13 | Alien Bolt |

| 6 | Flat Gasket |

| 4.1 | O-Ring |

| 4.2 | O-Ring |

| 4.3 | O-Ring |

| 4.4 | O-Ring |

| 4.5 | O-Ring |

| 4.6 | O-Ring |

| 4.7 | O-Ring |

| 17 | Insert |

| 22 | Gland Plate |

| 1.1 | Seal Ring |

| 1.2 | Seal Ring |

| 2.1 | Mating Ring |

| 2.2 | Mating Ring |

| 10 | Spring |

| 11 | Spring |

| 16 | Drive Coller |