Leak Proof LPW881 / 88B2A/DG Replacement Seal

John Crane Type 32D replacement Mechanical seal

Burgmann MFL85N Replacement Mechanical seal

>HIFAB SSDB-E2/E4 Replacement Mechanical Seal

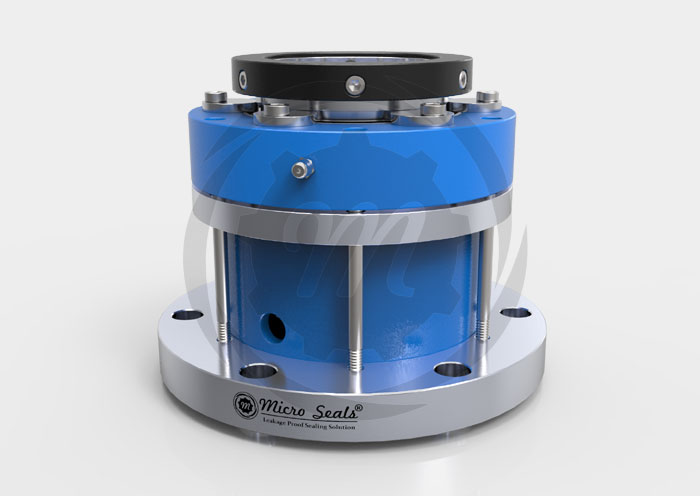

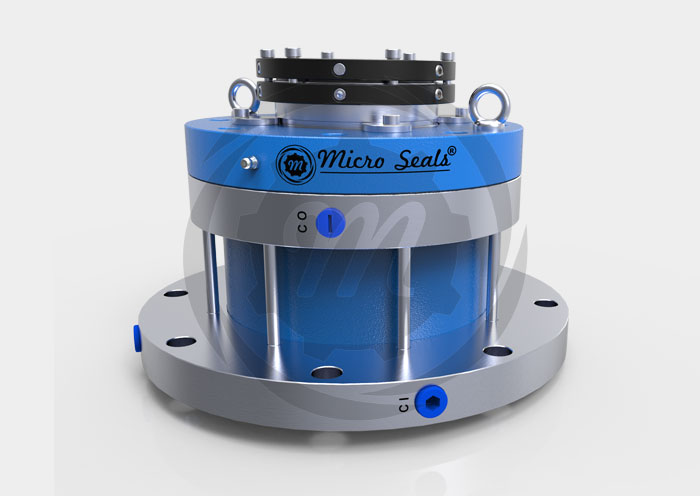

DRY RUNNING MIXER MECHANICAL SEALS

D50/D51B Dry Running Agitator Mixer Seals For Vertical Type Agitation Equipment, Pharma Reactors, Fermentors and Rotocon Dryers.

Single Dry Running Mixer Seal Simple and rugged drive design that can withstand shaft movement, vibration & deflection. This Seal is design eliminates the need for auxiliary equipment for cooling & lubrication that is required for mixer application. Since there is no use of barrier fluid, thus eliminates the possibility of product contamination can be used in high vacuum applications. These seals are basically used on top entry agitators for food and pharmaceutical industries where contamination of the media with any other liquid inside the agitator is not permissible. These seals do not require any external lubrication to the seal faces, hence these seals are known as dry running seals.

Dry Running Agitator Mechanical Seals

Dry Running Mixer Seals is a multiple spring externally mounted, Reverse Balanced Seal with O-ring as secondary sealing member.

Dry Running Agitator Seals are available with cartridge, non-cartridge & with bearing assembly. Dry Running Seals design eliminates the need of auxiliary equipment for cooling & lubrication that is required for mixer application. Since there is no use of barrier fluid, thus eliminates the possibility of product contamination.

Dry Running Seals don’t require any external media for lubricating the faces, that is why they are known as dry running seals.

Large clearance between rotating shaft/sleeve and mating ring permits higher deflection of the shaft, invariably associated with Top Entry Agitators.

- For top entry drives

- Dry-running

- Single seal

- Balanced

- Outboard mounted

- Multiple springs rotating

- Independent of direction of rotation

| Seal Ring Face | : Carbon, Silicon, TC |

| Mating Ring Face | : Silicon, TC |

| Secondary Seals | : Viton/PTFE/Nitrile |

| Metal Parts | : SS 316, 304L |

| Pressure | : up to 1.40 MPa |

| Temperature | : (-)10c to (+)150c |

| Speed | : up to 1 m/s |

| Size | : 25 mm to 150 mm |

Dry running Mixer seals are widely used in top entry low RPM mixers, agitators & vessels in pharmaceuticals & chemical industries.

| Item No | Description |

|---|---|

| 1 | Seal Ring |

| 2 | Mating Ring |

| 4.1 | O-Ring |

| 4.2 | O-Ring |

| 4.3 | O-Ring |

| 6 | Square Packing |

| 6 | Wedge |

| 8 | Oil Seal |

| 10 | Spring |

| 15 | Thrust Ring |

| 17 | Retainer |

| 20 | Sleeve |

| 22 | Gland Plate |