AGITATOR MECHANICAL SEALS

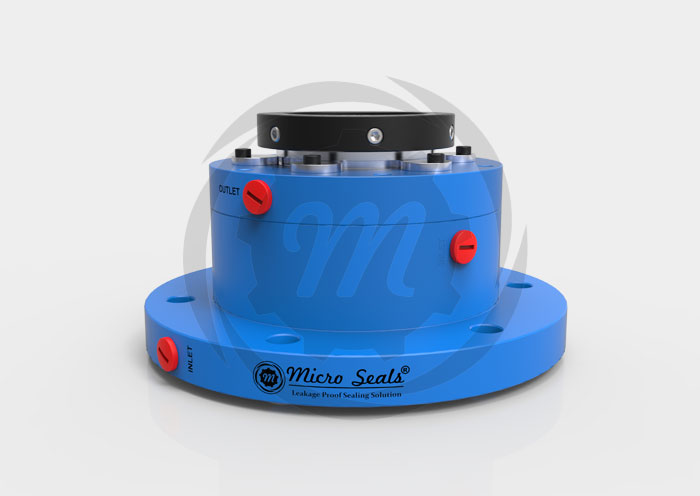

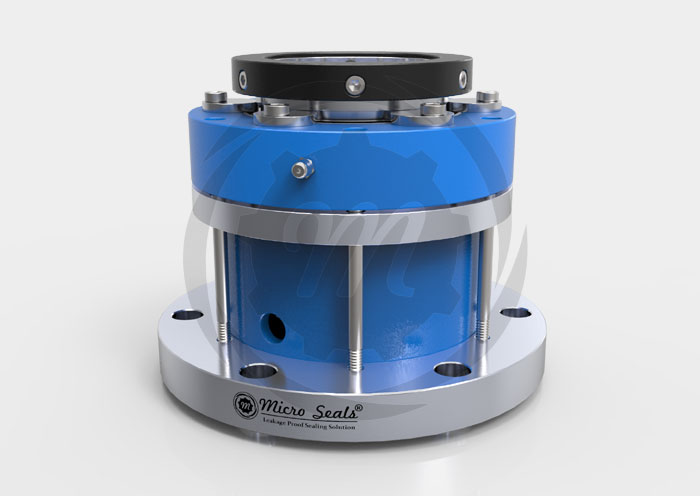

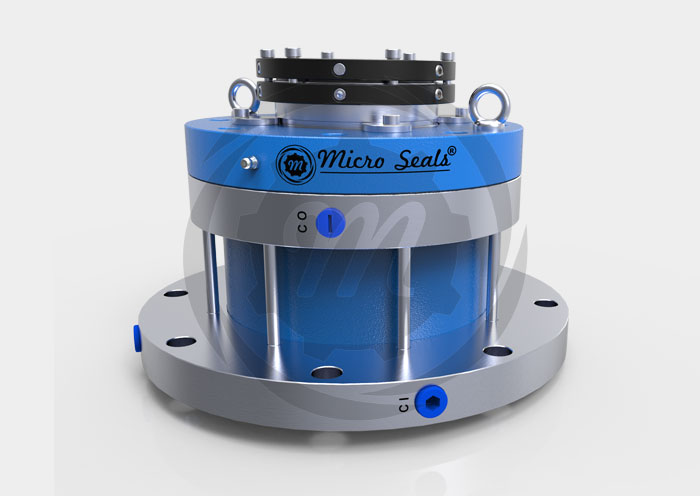

W52/W53B Top Entry Agitator Mixer Mechanical Seals For Vertical Type Glass / Polymer Lined Reactors, Cladded Reactors and Agitation Equipment

Our large Performance Agitator Reactors are designed using Magnetic drive couplings or Conventional Single / Double Mechanical Seals depending on the application. Our company manufacture and assembled High Pressure Double Mechanical Seals are applied on mixers, agitators & reactors seals. These double mechanical seals are created for handling hard & hazardous fluids. The design incorporates bearings located very close to the seal to avoid the cantilever effect at the seal area. A standard cooling jacket is provided in the seals to destroy the maximum amount of heat generated by the seals. Seals can be given without bearing if the equipment’s bearings are very close to sealing area. We also offer double dry running seals to avoid the risk of contaminating costly batches.

Agitator Mixer Mechanical Seals(trial)

Agitator Mechanical Seals are designed for handling severe services including products emitting toxic vapours during reaction process.

Agitator Mixer Seal design incorporates bearing located very close to the seal. This standard feature effectively arrests the shaft whip for smooth and trouble free operation enabling enhanced seal life.

The cooling jacket, also a standard feature, helps to maintain cool environment around the seal.

Large clearance between rotating shaft/sleeve and mating ring permits higher deflection of the shaft, invariably associated with Top Entry Agitators.

- For top entry drives

- Single seals

- Balanced or Unbalanced mechanism

- Independent of direction of rotation

- Multiple springs rotating

- Liquid-lubricated

- Cooling provision by jacketing

- With and without bearing

| Seal Ring Face | : Carbon, Silicon, TC |

| Mating Ring Face | : Silicon, TC |

| Secondary Seals | : Viton / PTFE / FEP |

| Metal Parts | : SS 316, SS-304, Hast-B |

| Pressure | : up to 1.40 MPa |

| Temperature | : (-)10c to (+)150c |

| Speed | : up to 1 m/s |

| Size | : 5 mm to 150 mm |

Agitator Mechanical Seals are used on various types of equipment like a mixer, agitator, Vessel, Glass line Reactors and driers in pharmaceuticals, paints, pulp &plastic industries.

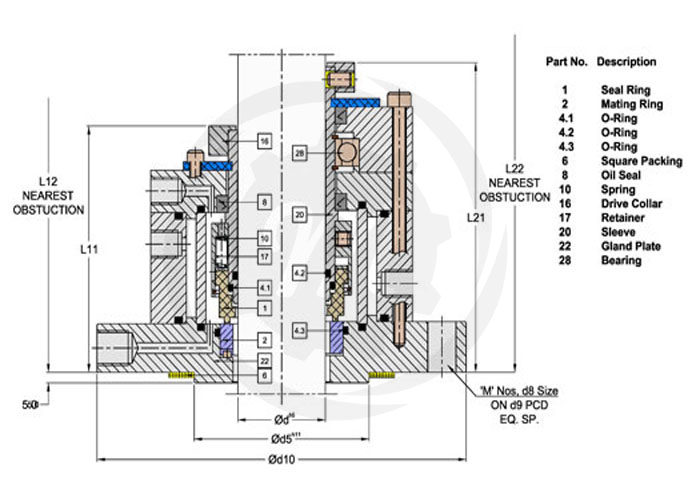

| Item No | Description |

|---|---|

| 1 | Seal Ring |

| 2 | Mating Ring |

| 4.1 | O-Ring |

| 4.2 | O-Ring |

| 4.3 | O-Ring |

| 6 | Square Packing |

| 8 | Oil Seal |

| 10 | Spring |

| 16 | Drive Coller |

| 17 | Retainer |

| 20 | Sleeve |

| 22 | Gland Plate |

| 18 | Bearing |